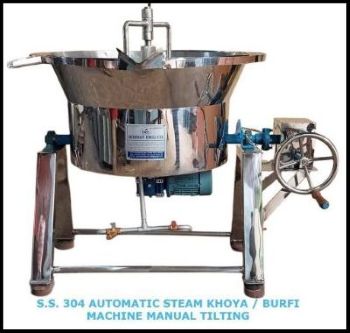

India's rich tradition of sweets, especially milk-based confections like khoya and burfi, has been a cherished part of its culinary heritage. As demand grows, so does the need for efficient, hygienic, and automated machinery to produce these delicacies at scale. Enter the S.S. 304 Automatic Steam Khoya / Burfi Machine by Bombay Engg. Co.—a pioneering solution designed to revolutionize confectionery manufacturing.

About Bombay Engg. Co.

Established as a trusted name in the engineering sector, Bombay Engg. Co. specializes in designing and manufacturing high-quality food processing machinery tailored for Indian sweet producers. Their commitment to quality, innovation, and customer satisfaction has made them a leader in this niche industry.

What is the S.S. 304 Automatic Steam Khoya / Burfi Machine?

This state-of-the-art machine is engineered specifically for the efficient production of khoya (milk solids) and burfi (a popular milk-based sweet). Key features include:

- Material Quality: Constructed with S.S. 304 stainless steel, ensuring durability, hygiene, and resistance to corrosion—crucial for food-grade equipment.

- Automatic Operation: Designed for full automation, reducing manual effort and ensuring consistent product quality.

- Steam Heating: Utilizes steam heating technology for uniform and controlled cooking, which preserves the authentic taste and texture of the sweets.

- Manual Tilting Mechanism: Features a manual tilting system that facilitates easy discharge of the cooked khoya or mixture, simplifying the process and reducing operational time.

- Capacity & Efficiency: Available in various capacities to suit different scale operations—from small local producers to large industrial units.

Benefits of Using the Automatic Steam Khoya / Burfi Machine

- Hygienic & Safe: Made from food-grade stainless steel, ensuring compliance with safety standards.

- Time-Saving: Automation and efficient heating drastically reduce production time.

- Consistent Quality: Precise temperature control results in uniform texture and taste.

- Ease of Operation: Manual tilting makes the discharge process straightforward, minimizing labor and effort.

- Cost-Effective: Reduces manpower and operational costs over time.

Why Choose Bombay Engg. Co.?

- Proven Expertise: Years of experience in manufacturing food processing machinery.

- Customization: Options to customize the machine as per specific production needs.

- After-Sales Support: Reliable maintenance services and spare parts availability.

- Affordable Pricing: Competitive rates suitable for various budget sizes.

Final Thoughts

In the competitive world of Indian sweets manufacturing, upgrading to modern machinery like the S.S. 304 Automatic Steam Khoya / Burfi Machine can significantly enhance productivity, product quality, and profitability. Bombay Engg. Co.'s innovative design, durability, and commitment to excellence make this machine an ideal investment for sweet makers aiming to scale their operations efficiently.

Interested in modernizing your sweet production process? Contact Bombay Engg. Co. today to learn more about their machinery options and how they can help elevate your confectionery business!

Note: This blog aims to provide an overview of the machine. For detailed specifications and pricing, please reach out directly to Bombay Engineering Co.